Inpage Navigation Section: Overview

The newest member of the championship winning ZX line up is a 250cc beast, with a big bore attitude. The only in-line four model in its class, the Ninja ZX-25R features an all new in-line four engine which delivers superior performance, eclipsing all other bikes in the 250cc to 300cc field.

Colour

Show all

Show less

₱406,000.00

Inpage Navigation Section: Gallery

Inpage Navigation Section: Features & Specs

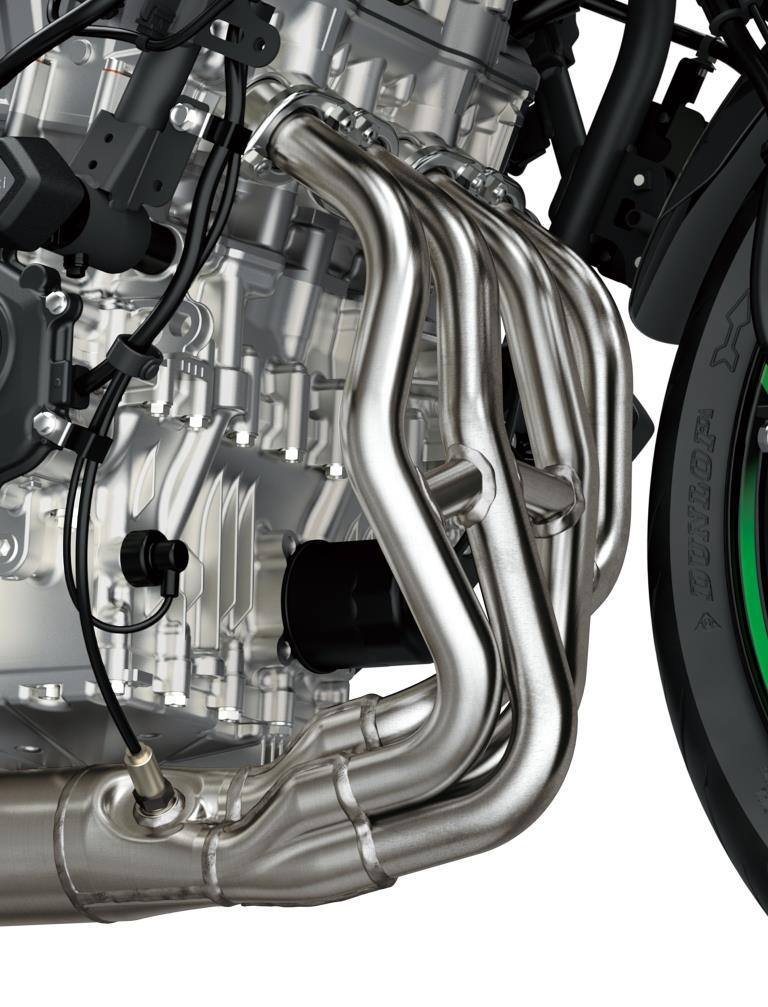

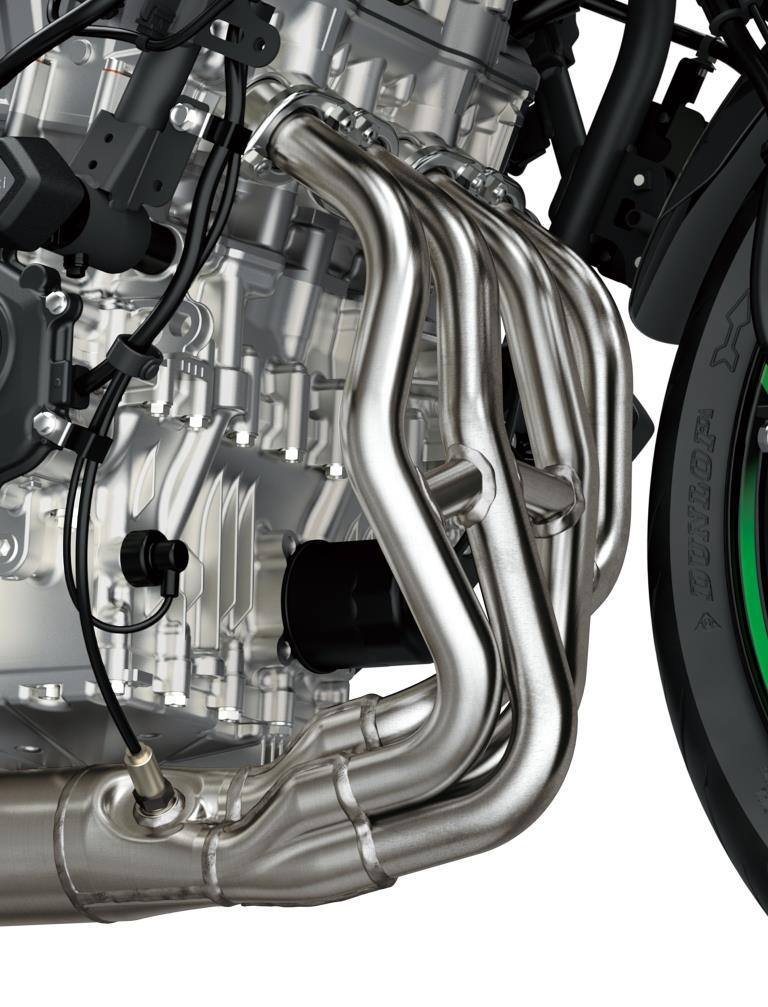

The Ninja ZX-25R is equipped with an all-new engine design – a 250cc, In-Line Four, Liquid Cooled engine. This engine delivers performance that eclipses other 250cc models in the field.

The Ninja ZX-25R is equipped with an all-new engine design – a 250cc, In-Line Four, Liquid Cooled engine. This engine delivers performance that eclipses other 250cc models in the field.

The 37mm inverted front fork uses a Showa SFF-BP (Separate Function Fork – Big Piston) front suspension. This advanced fork offers both racetrack performance and everyday usability.

The 37mm inverted front fork uses a Showa SFF-BP (Separate Function Fork – Big Piston) front suspension. This advanced fork offers both racetrack performance and everyday usability.

Key chassis dimensions were inspired by Kawasaki’s World Superbike Ninja ZX-10RR racing bike. Designed using Kawasaki’s advanced dynamic rigidity analysis, the all-new lightweight trellis frame delivers the required balance of strength and chassis flex to achieve nimble super sport-style handling.

Key chassis dimensions were inspired by Kawasaki’s World Superbike Ninja ZX-10RR racing bike. Designed using Kawasaki’s advanced dynamic rigidity analysis, the all-new lightweight trellis frame delivers the required balance of strength and chassis flex to achieve nimble super sport-style handling.

The Ninja ZX-25R is equipped with an all-new engine design – a 250cc, In-Line Four, Liquid Cooled engine. This engine delivers performance that eclipses other 250cc models in the field.

The Ninja ZX-25R is equipped with an all-new engine design – a 250cc, In-Line Four, Liquid Cooled engine. This engine delivers performance that eclipses other 250cc models in the field.

The 37mm inverted front fork uses a Showa SFF-BP (Separate Function Fork – Big Piston) front suspension. This advanced fork offers both racetrack performance and everyday usability.

The 37mm inverted front fork uses a Showa SFF-BP (Separate Function Fork – Big Piston) front suspension. This advanced fork offers both racetrack performance and everyday usability.

Key chassis dimensions were inspired by Kawasaki’s World Superbike Ninja ZX-10RR racing bike. Designed using Kawasaki’s advanced dynamic rigidity analysis, the all-new lightweight trellis frame delivers the required balance of strength and chassis flex to achieve nimble super sport-style handling.

Key chassis dimensions were inspired by Kawasaki’s World Superbike Ninja ZX-10RR racing bike. Designed using Kawasaki’s advanced dynamic rigidity analysis, the all-new lightweight trellis frame delivers the required balance of strength and chassis flex to achieve nimble super sport-style handling.

3-Mode KTRC (Kawasaki TRaction Control), Kawasaki's most advanced traction control system, offers a selection of modes to suit a variety of riding situations, from sport riding to touring.

3-mode KTRC combines the traction control technology of both 1-mode KTRC, which provides enhanced stability in slippery situations by preventing wheel slip, and S-KTRC, which helps maintain optimum traction in sport riding situations by predicting the rear wheel slip ratio during acceleration, into a single system. The convenient handle switch allows the type of traction control to be changed instantly by selecting one of the three modes, even while riding. Modes 1 and 2 maintain optimum traction during cornering, like S-KTRC. Designed with sport riding in mind, they enable sharp acceleration out of corners by maximizing forward drive from the rear wheel. Modes 1 and 2 differ in the amount that they intervene. Mode 1, set for dry, good-grip road conditions, maintains the ideal slip ratio to ensure optimum traction. Mode 3 operates like 1-mode KTRC, reducing power to allow grip to be regained when rear wheel spin is detected. It is ideal when riding in slippery conditions or in the wet. Enabling riders to easily change traction control character, 3-mode KTRC is Kawasaki's most advanced engine management system.

ABS (Anti-lock Brake System) ensures stable braking performance by preventing wheel lock during braking.

Sudden over-application of the brakes, or braking on low-grip surfaces (surfaces with a low coefficient of friction) such as wet asphalt or manhole covers may cause a motorcycle's wheel(s) to lock up and slip. ABS was developed to prevent such incidents. Kawasaki ABS systems are controlled by high precision and highly reliable programming formulated based on thorough testing of numerous riding situations. By ensuring stable braking performance, they offer rider reassurance that contributes to greater riding enjoyment. And to meet the special requirements of certain riders, specialised ABS systems are also available. For example, KIBS (Kawasaki Intelligent anti-lock Brake System) is a high-precision brake system designed specifically for supersport models, enabling sport riding to be enjoyed by a wider range of riders. And by linking the front and rear brakes, K-ACT (Kawasaki Advanced Coactive-braking Technology) ABS provides the confidence to enjoy touring on heavyweight models. Kawasaki is continually working on the development of other advanced ABS systems.

Horizontal Back-link Rear Suspension arranges its shock unit horizontally, greatly contributing to efficient use of space and mass centralisation.

Compared to Kawasaki's traditional Uni-Trak rear suspension, which mounts the shock unit vertically, with Horizontal Back-link rear suspension, the shock unit is almost horizontal. Kawasaki's original suspension arrangement locates the shock unit very close to the bike's centre of gravity, greatly contributing to mass centralisation. And because there is no linkage or shock unit protruding beneath the swingarm, this frees up space for a larger exhaust pre-chamber (an exhaust expansion chamber situated just upstream of the silencer). With a larger pre-chamber, silencer volume can be reduced, and heavy exhaust components can be concentrated closer to the centre of the bike, further contributing to mass centralisation. The result is greatly improved handling. Another benefit is that the shock unit is placed far away from exhaust heat. Because it is more difficult for heat from the exhaust system to adversely affect suspension oil and gas pressure, suspension performance is more stable. Horizontal Back-link rear suspension offers numerous secondary benefits like this.

Electronic Throttle Valves allow the ECU to deliver the ideal amount of fuel and air to the engine.

Kawasaki's fully electronic throttle actuation system enables the ECU to control the volume of both the fuel (via fuel injectors) and the air (via throttle valves) delivered to the engine. Ideal fuel injection and throttle valve position results in smooth, natural engine response and the ideal engine output. The system also makes a significant contribution to reduced emissions. Electronic throttle valves also enable more precise control of electronic engine management systems like S-KTRC and KTRC, and allow the implementation of electronic systems like KLCM, Kawasaki Engine Brake Control, and Electronic Cruise Control.

The Economical Riding Indicator is a mark appearing on the instrument panel to indicate favourable fuel consumption, encouraging fuel efficient riding.

Using high-precision electronic control for engine management, Kawasaki models can achieve a high level of fuel efficiency. However, fuel consumption is greatly affected by throttle use, gear selection, and other elements under the rider's control. The Economical Riding Indicator is a function that indicates when current riding conditions are consuming a low amount of fuel. The system continuously monitors fuel consumption, regardless of vehicle speed, engine speed, throttle position and other riding conditions. When fuel consumption is low for a given speed (i.e. fuel efficiency is high), an "ECO" mark appears on the instrument panel's LCD screen. By riding so that the "ECO" mark remains on, fuel consumption can be reduced. While effective vehicle speed and engine speed may vary by model, paying attention to conditions that cause the "ECO" mark to appear can help riders improve their fuel efficiency – a handy way to increase cruising range. Further, keeping fuel consumption low also helps minimise negative impact on the environment.

Designed to help riders maximise their acceleration on the circuit by enabling clutchless upshifts with the throttle fully open, KQS detects that the shift lever has been actuated and sends a signal to the ECU to cut ignition so that the next gear can be engaged without having to use the clutch. On models that offer clutchless downshifts, during deceleration the system automatically controls engine speed so that the next lower gear can be selected without operating the clutch.

Based on racing technology, the Assist & Slipper Clutch acts as both a back-torque limiter and a self-servo mechanism that enables a lighter clutch lever pull.

Based on feedback from racing activities, the Assist & Slipper Clutch uses two types of cams (an assist cam and a slipper cam) to either drive the clutch hub and operating plate together or apart. Under normal operation, the assist cam functions as a self-servo mechanism, pulling the clutch hub and operating plate together to compress the clutch plates. This allows the total clutch spring load to be reduced, resulting in a lighter clutch lever feel when operating the clutch. When excessive engine braking occurs as a result of quick downshifts (or an accidental downshift) the slipper cam comes into play, forcing the clutch hub and operating plate apart. This relieves pressure on the clutch plates to reduce back-torque and helps prevent the rear tyre from hopping and skidding. This race-style function is particularly useful when sport or track riding.

Power Mode selection allows engine power delivery to be changed to suit the riding situation.

Models equipped with multiple Power Modes offer riders an easily selectable choice of engine power delivery to suit riding conditions or preference. In addition to Full Power mode, one (Low) or two (Middle, Low) alternate mode(s) in which maximum power is limited and throttle response is milder are provided.

3-Mode KTRC (Kawasaki TRaction Control), Kawasaki's most advanced traction control system, offers a selection of modes to suit a variety of riding situations, from sport riding to touring.

3-mode KTRC combines the traction control technology of both 1-mode KTRC, which provides enhanced stability in slippery situations by preventing wheel slip, and S-KTRC, which helps maintain optimum traction in sport riding situations by predicting the rear wheel slip ratio during acceleration, into a single system. The convenient handle switch allows the type of traction control to be changed instantly by selecting one of the three modes, even while riding. Modes 1 and 2 maintain optimum traction during cornering, like S-KTRC. Designed with sport riding in mind, they enable sharp acceleration out of corners by maximizing forward drive from the rear wheel. Modes 1 and 2 differ in the amount that they intervene. Mode 1, set for dry, good-grip road conditions, maintains the ideal slip ratio to ensure optimum traction. Mode 3 operates like 1-mode KTRC, reducing power to allow grip to be regained when rear wheel spin is detected. It is ideal when riding in slippery conditions or in the wet. Enabling riders to easily change traction control character, 3-mode KTRC is Kawasaki's most advanced engine management system.

ABS (Anti-lock Brake System) ensures stable braking performance by preventing wheel lock during braking.

Sudden over-application of the brakes, or braking on low-grip surfaces (surfaces with a low coefficient of friction) such as wet asphalt or manhole covers may cause a motorcycle's wheel(s) to lock up and slip. ABS was developed to prevent such incidents. Kawasaki ABS systems are controlled by high precision and highly reliable programming formulated based on thorough testing of numerous riding situations. By ensuring stable braking performance, they offer rider reassurance that contributes to greater riding enjoyment. And to meet the special requirements of certain riders, specialised ABS systems are also available. For example, KIBS (Kawasaki Intelligent anti-lock Brake System) is a high-precision brake system designed specifically for supersport models, enabling sport riding to be enjoyed by a wider range of riders. And by linking the front and rear brakes, K-ACT (Kawasaki Advanced Coactive-braking Technology) ABS provides the confidence to enjoy touring on heavyweight models. Kawasaki is continually working on the development of other advanced ABS systems.

Horizontal Back-link Rear Suspension arranges its shock unit horizontally, greatly contributing to efficient use of space and mass centralisation.

Compared to Kawasaki's traditional Uni-Trak rear suspension, which mounts the shock unit vertically, with Horizontal Back-link rear suspension, the shock unit is almost horizontal. Kawasaki's original suspension arrangement locates the shock unit very close to the bike's centre of gravity, greatly contributing to mass centralisation. And because there is no linkage or shock unit protruding beneath the swingarm, this frees up space for a larger exhaust pre-chamber (an exhaust expansion chamber situated just upstream of the silencer). With a larger pre-chamber, silencer volume can be reduced, and heavy exhaust components can be concentrated closer to the centre of the bike, further contributing to mass centralisation. The result is greatly improved handling. Another benefit is that the shock unit is placed far away from exhaust heat. Because it is more difficult for heat from the exhaust system to adversely affect suspension oil and gas pressure, suspension performance is more stable. Horizontal Back-link rear suspension offers numerous secondary benefits like this.

Electronic Throttle Valves allow the ECU to deliver the ideal amount of fuel and air to the engine.

Kawasaki's fully electronic throttle actuation system enables the ECU to control the volume of both the fuel (via fuel injectors) and the air (via throttle valves) delivered to the engine. Ideal fuel injection and throttle valve position results in smooth, natural engine response and the ideal engine output. The system also makes a significant contribution to reduced emissions. Electronic throttle valves also enable more precise control of electronic engine management systems like S-KTRC and KTRC, and allow the implementation of electronic systems like KLCM, Kawasaki Engine Brake Control, and Electronic Cruise Control.

The Economical Riding Indicator is a mark appearing on the instrument panel to indicate favourable fuel consumption, encouraging fuel efficient riding.

Using high-precision electronic control for engine management, Kawasaki models can achieve a high level of fuel efficiency. However, fuel consumption is greatly affected by throttle use, gear selection, and other elements under the rider's control. The Economical Riding Indicator is a function that indicates when current riding conditions are consuming a low amount of fuel. The system continuously monitors fuel consumption, regardless of vehicle speed, engine speed, throttle position and other riding conditions. When fuel consumption is low for a given speed (i.e. fuel efficiency is high), an "ECO" mark appears on the instrument panel's LCD screen. By riding so that the "ECO" mark remains on, fuel consumption can be reduced. While effective vehicle speed and engine speed may vary by model, paying attention to conditions that cause the "ECO" mark to appear can help riders improve their fuel efficiency – a handy way to increase cruising range. Further, keeping fuel consumption low also helps minimise negative impact on the environment.

Designed to help riders maximise their acceleration on the circuit by enabling clutchless upshifts with the throttle fully open, KQS detects that the shift lever has been actuated and sends a signal to the ECU to cut ignition so that the next gear can be engaged without having to use the clutch. On models that offer clutchless downshifts, during deceleration the system automatically controls engine speed so that the next lower gear can be selected without operating the clutch.

Based on racing technology, the Assist & Slipper Clutch acts as both a back-torque limiter and a self-servo mechanism that enables a lighter clutch lever pull.

Based on feedback from racing activities, the Assist & Slipper Clutch uses two types of cams (an assist cam and a slipper cam) to either drive the clutch hub and operating plate together or apart. Under normal operation, the assist cam functions as a self-servo mechanism, pulling the clutch hub and operating plate together to compress the clutch plates. This allows the total clutch spring load to be reduced, resulting in a lighter clutch lever feel when operating the clutch. When excessive engine braking occurs as a result of quick downshifts (or an accidental downshift) the slipper cam comes into play, forcing the clutch hub and operating plate apart. This relieves pressure on the clutch plates to reduce back-torque and helps prevent the rear tyre from hopping and skidding. This race-style function is particularly useful when sport or track riding.

Power Mode selection allows engine power delivery to be changed to suit the riding situation.

Models equipped with multiple Power Modes offer riders an easily selectable choice of engine power delivery to suit riding conditions or preference. In addition to Full Power mode, one (Low) or two (Middle, Low) alternate mode(s) in which maximum power is limited and throttle response is milder are provided.

| Engine type | Liquid-cooled, 4-stroke, in-line four |

|---|---|

| Compression ratio | 12.5:1 |

| Valve system | DOHC |

| Bore x stroke | 50.0 x 31.8 mm |

| Displacement | 250 cm³ |

| Fuel system | Fuel injection |

| Lubrication | Forced lubrication, wet sump |

| Starting system | Electric |

| Ignition system | Battery & Coil (transistorised ignition) |

| Maximum power | 34.5 kW {47 PS} / 15,500 rpm |

|---|---|

| Maximum power with RAM Air | 35.2 kW {48 PS} / 15,500 rpm |

| Maximum torque | 22.0 N•m {2.2 kgf•m} / 12,500 rpm |

| Transmission | 6-speed, return shift |

| Clutch | Wet, multi disc |

| Primary reduction ratio | 2.900 (87/30) |

| Gear ratios 1st | 2.929 (41/14) |

| Gear ratios 2nd | 2.056 (37/18) |

| Gear ratios 3rd | 1.619 (34/21) |

| Gear ratios 4th | 1.333 (32/24) |

| Gear ratios 5th | 1.154 (30/26) |

| Gear ratios 6th | 1.037 (28/27) |

| Final drive | Chain |

| Final reduction ratio | 3.571 (50/14) |

| Frame type | Trellis, high-tensile steel |

|---|---|

| Trail | 99 mm |

| Wheel travel front | 120 mm |

| Wheel travel rear | 116 mm |

| L x W x H | 1,980 x 750 x 1,110 mm |

| Steering angle L/R | 35° / 35° |

| Wheel base | 1,380 mm |

| Ground clearance | 125 mm |

| Fuel capacity | 15.0 litres |

| Seat height | 785 mm |

| Curb mass | 183 kg |

| Front brake type | Single disc |

|---|---|

| Rear brake type | Single disc |

| Front suspension type | Inverted fork |

| Rear suspension type | Horizontal Back-link with spring preload adjustability |

Inpage Navigation Section: Accessories